25 Ton Modern Rice Mill Plant

This 25T/D rice production equipment is suitable for medium-scale rice milling process, which can process about 1000-1200kg of rice per hour and obtain about 1100-1350kg of white rice. And the capacity and machine of rice milling equipment can be customized according to your special requirements.

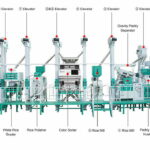

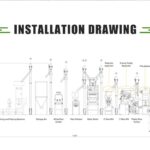

Our machines use the most advanced automation features to simplify the rice milling process, ensuring consistent and high-quality output with minimal human intervention. The main machines of this rice mill are rice de-stoner, rice husker, gravity rice separator, rice mill, secondary rice mill, color sorter, polisher, white rice grader and packaging machine.

Product Details of The 25T/D Rice Mill Plant

| Product name | Model | Power(kw) | Unit |

| 20D Miller | MTCP20D | 30.65 | set |

| Emery Roller Rice Whiteners | MNMS15F | 15 | set |

| Single Roll Polishing Machine | MPG12.5 | 26 | set |

| White Rice Grader | MMJP63*3 | 0.75 | pcs |

| Color sorter include compressor,tank, platform,bin | 6SXM-120(CCD) | 7 | set |

video of 25 Ton Rice Mill Plant work

Some on-site installation pictures

Modern Rice Milling Plant Features

Get High quality rice, low broken rice rate

Dehulling paddy with rollers reduces the broken rice rate by 90%.

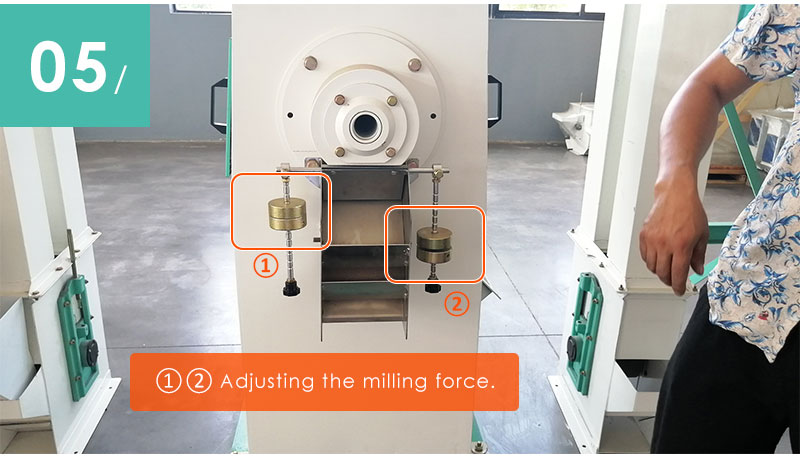

Multiple parallel combined rice mills work continuously. Rice is milled through a multi-pass program. Each program gently grinds the surface of the brown rice once to prevent the rice grains from breaking.

Different rice milling machine accessories are used according to the shape of the rice; if the shape of the customer’s rice is long (the thickness of the rice is low), we will configure sand rollers for rice milling, and round rice will use iron rollers for the rice milling process. This can not only ensure the rice milling effect, but also reduce the broken rice rate. The rice milling machine adopts the rice milling technology with double air ducts, which is driven by a belt, and the helical tooth surface is reversed, with low noise and stable performance; The strong pulling wind makes the finished rice bran powder less content, the rice temperature is lower, and the brokenness is less.

Efficient Cleaning, No Dust

Absorption stone removal and rotary cleaning screen are used to remove sundries in the grain, such as gravel, iron dust, platycodon, etc. At the same time, the dust pollution during feeding is reduced.

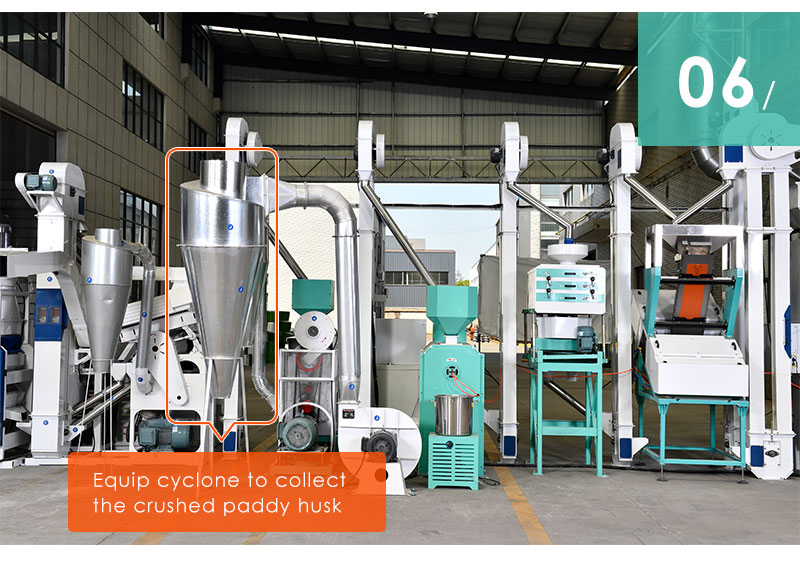

At the same time, our rice mill is equipped with Cyclone and fan to collect rice husks and remove light dust impurities.

Permutation And Combination Structure

Simple structure, neat and beautiful, low energy consumption, convenient disassembly and maintenance; main operations are on one side, and the whole machine runs smoothly

Customized Size

The requirements for the workshop are not high, and the size can be customized and 3D layout drawings can be provided. It is an ideal rice processing equipment for township grain offices (stations), individual rice factories and farms.

High Economic Benefits Of Rice Bran By-Products

Using the self-made pulverizing system, the large chaff and the clear chaff can be mixed into the pulverizer at the same time to be processed into the whole chaff, so that the by-products can be fully utilized, and the economic benefit of the user is increased.

The rice bran produced can be sold; it can also be collected and crushed to make feed; or recycled to make mechanical charcoal

Wide Range Of Applications

Shuliy rice mill is suitable for rice processing in different countries, regions, processing plants of different scales and different varieties of rice.